About Monel and its Uses

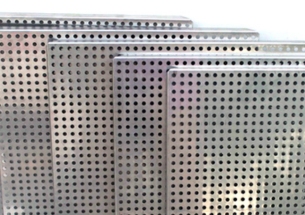

Monel is a group of nickel alloys, primarily composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel alloys are known for their high strength and corrosion resistance, making them ideal for use in harsh environments such as marine applications, chemical processing, and aerospace industries.

Monel products are used in a wide range of industries, including oil and gas, chemical processing, marine engineering, and aerospace. Grade 400 and K500 Monel alloys are particularly suitable for applications in seawater environments due to their excellent resistance to corrosion and erosion.

Properties of Monel

| Form | Condition | Tensile Strength (ksi) | Yield Strength (ksi) | % Elongation | Brinell hardness | Rockwell B Hardness | Tensile Strength (Mpa) | Yield Strength (Mpa) |

| Rod and Bar | Annealed | 75-90 | 25-50 | 60-35 | 110-149 | 60-80 | 517-620 | 172-345 |

| Rod and Bar |

Hot-Finished (except Hexagons over 2 1/8 inches and Angles |

80-11 | 40-10 | 60-30 | 140-241 | 75-10 | 552-758 | 276-690 |

| Rod and Bar |

Hot-Finished Hexagons over 2 1/ inches and Angles |

75-10 | 30-55 | 50-30 | 130-184 | 72-90 | 517-690 | 207-379 |

| Rod and Bar | Cold-Drawn, Stress-Relieved | 84-12 | 55-10 | 40-22 | 160-225 | 85-20 | 579-827 | 379-690 |

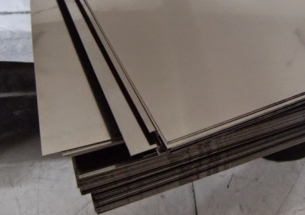

| Plate | Hot Rolle | 75-95 | 40-75 | 45-30 | 125-215 | 70-96 | 517-655 | 276-517 |

| Plate | Hot Rolled, Annealed | 70-85 | 28-50 | 50-35 | 110-140 | 60-76 | 482-586 | 193-345 |

| Sheet | Annealed | 70-85 | 30-45 | 45-35 | 65-80 | 482-586 | 207-310 | |

| Sheet | Cold Rolled, hard | 100-120 | 90-11 | 15-02 | Min. 93 | 690-827 | 621-758 | |

| Cold Rolled Strip | Annealed | 70-85 | 25-45 | 55-35 | Max. 68 | 482-586 | 172-310 | |

| Cold Rolled Strip | Spring Temper | 100-140 | 90-13 | 15-02 | Min. 98 | 690-965 | 621-896 | |

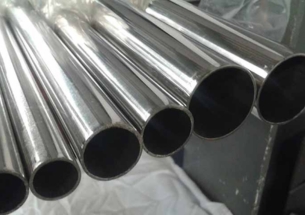

| Seamless pipe and tub | Cold Drawn, Annealed | 70-85 | 25-45 | 50-35 | Max 7 | 482-586 | 172-310 | |

| Seamless pipe and tub | Cold Drawn, Stress Relieved | 100-140 | 55-10 | 35-15 | 85-10 | 586-827 | 379-690 | |

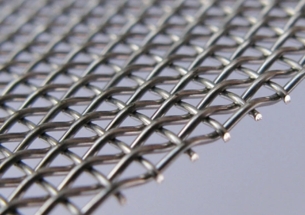

| Cold Drawn Wire | Annealed | 70-95 | 30-55 | 45-25 | 482-655 |

Grades of Monel

|

Monel Grade/Trade Name |

ASTM/AISI Alloy Type |

UNS No. |

%Ni |

%Cu |

%Fe |

%Mn |

%Al |

%Ti |

%Si |

|

Monel 400 |

B 127/ B 16 |

N04400 |

Min. 63 |

28-34 |

Max 2.5 |

Max 2.0 |

|

|

Max 0.5 |

|

Monel 401 |

|

N04401 |

Min. 63 |

28-34 |

Max 2.5 |

Max 2.0 |

|

|

Max 0.5 |

|

Monel 404 |

|

N04404 |

52-57 |

Remaining |

Max 0.5 |

Max 0.1 |

Max 0.0 |

|

Max 0.1 |

|

Monel 405 |

B 164 |

N04405 |

Min. 63 |

28-34 |

Max 2.5 |

Max 2.0 |

|

|

Max 0.5 |

|

Monel K500 |

B 865 |

N05500 |

Min. 63 |

27-33 |

Max 2.0 |

Max 1.5 |

2.3-3.1 |

0.35-0.85 |