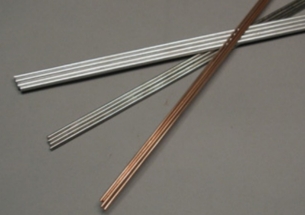

Nickel 200/201 Filler Wire

Siddhgiri Tubes is proud to introduce our premium Nickel 200/201 filler wire, meticulously crafted to meet the exacting demands of welding applications across various industries. Nickel 200/201, renowned for its exceptional corrosion resistance and excellent thermal conductivity, emerges as the material of choice for filler wires in critical welding processes in industries such as chemical processing, aerospace, and marine engineering. Our Nickel 200/201 filler wire is meticulously manufactured using high-quality materials and advanced manufacturing techniques to ensure superior weldability, strength, and integrity.

Available in various diameters and spool sizes, our filler wire is tailored to suit a wide range of welding applications, from general fabrication to specialized projects requiring precise control and consistency. Each filler wire undergoes rigorous testing and inspection to ensure compliance with industry standards and customer specifications, guaranteeing dependable performance and quality welds. At Siddhgiri Tubes, customer satisfaction is paramount. Our experienced team is committed to providing personalized support and assistance at every stage, from product selection to technical guidance and after-sales service. Whether you require technical advice, custom solutions, or prompt delivery, Siddhgiri Tubes is here to meet your welding needs with professionalism and expertise.

Enquire NowNickel 200/201 Filler Wire Grade Specification

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 2.4066 | N02200 | NW 2200 | N-100M | NA 11 | НП-2 | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | - | NA 12 | НП-2 | LC-Ni 99 |

Nickel 200/201 Filler Wire Chemical Properties

| Element | Nickel Alloy 200 | Nickel Alloy 201 |

|---|---|---|

| Ni | 99.0 min | 99.0 min |

| C | 0.15 max | 0.02 max |

| Mn | 0.35 max | 0.35 max |

| S | 0.01 max | 0.01 max |

| Si | 0.1 max | 0.2 max |

| Cu | 0.25 max | 0.25 max |

| Mg | – | 0.15 max |

| Ti | – | 0.1 max |

| Fe | 0.4 max | 0.4 max |

Nickel 200/201 Filler Wire Chemical Properties

| Element | Nickel Alloy 200/201 |

|---|---|

| Density | 8.9 g/cm3 |

| Melting Point | 1446 °C (2635 °F) |

| Tensile Strength | Psi – 67000, MPa – 462 |

| Yield Strength (0.2%Offset) | Psi – 21500, MPa – 148 |

| Elongation | 45 % |

Cities We deliver:

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We deliver:

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad and Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.